Article: Additive Manufacture of Lighting Unit End Caps

(Derby, October 2021)

Overview

DB ESG are working in collaboration with Angel Trains on projects that incorporate 3D printing solutions (also known as additive manufacturing or AM) to address UK rail industry challenges. AM is particularly beneficial for reproducing obsolete or expensive rolling stock components, as it allows economical small production runs, with no tooling costs, in a much shorter lead time.

Individual Project Details

Class 43 Locomotives

Brush Traction was refurbishing Angel Trains’ HST power cars (Class 43 locomotives). Brush discovered, during this refurbishment work, that many small lighting fixture end caps were either missing or damaged. This component was obsolete and therefore completely unavailable for production, with only seven parts remaining in stock.

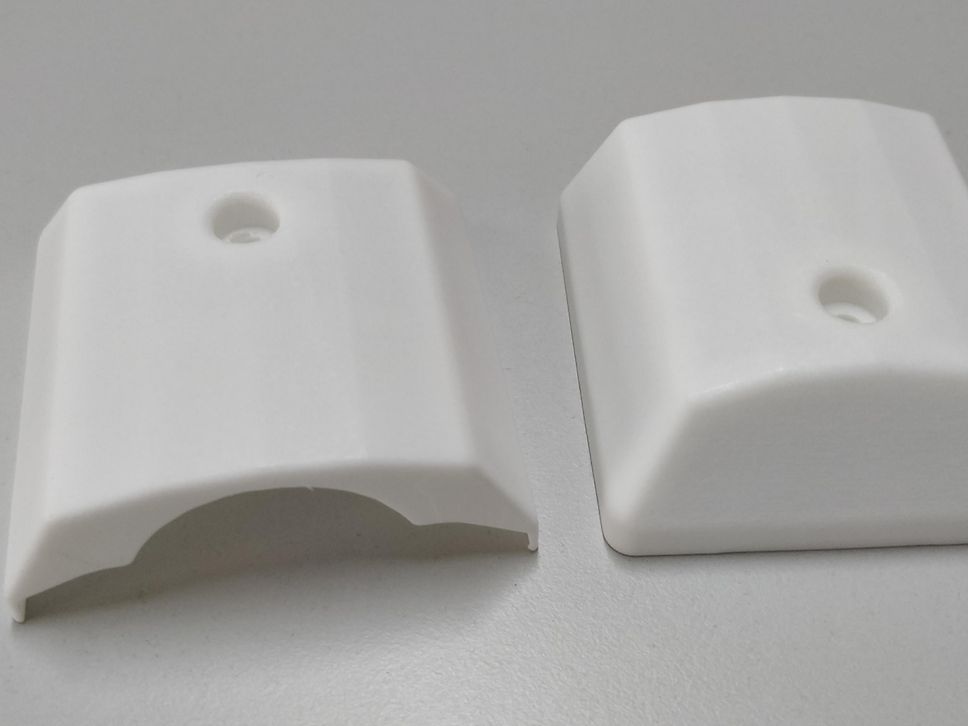

Angel Trains reverse-engineered the part, designed a replacement component for fused deposition modelling (FDM) and then 3D printed a prototype replacement in a white Acrylonitrile Butadiene Styrene polymer (ABS). Fire compliance was not necessary due to the part’s low weight.

After confirming the fit and function, DB ESG then procured 50 FDM printed replacement fittings at a unit cost of £14 and within a lead time of only 10 days. This allowed the refurbishment works to continue without the obsolescence issue causing project delays and consequential availability issues for the operators.

Class 153

Several small lighting fixture end caps used on fluorescent light fittings in the cab and guard’s compartment of Class 153 units operated by East Midlands Railways were missing. The light fitting was scanned to create a 3D model of the part. DB ESG modified this model to optimise it for production using additive manufacture and to improve the strength around failure areas.

A prototype was printed in FDM PETG (a glycol modified version of PET, a very widely used polyester based thermoplastic). Following the prototype production, fifteen caps were 3D printed in SLS Nylon 12 (selective laser sintering, a powder bed fusion AM technique for thermoplastic polymers).

These Nylon 12 production parts were post-processed to improve the surface finish. A fire assessment was undertaken to ensure fire compliance against the relevant standards requirements.

DB ESG also produced fifteen similar light end caps for the larger light fittings in the passenger saloon of the Class 153 units.