Article: Why is it important that welding is controlled for new build rolling stock? How does this apply to the repair and maintenance of existing rail vehicles? Which of the standards now apply to our rail sector?

Expert Opinion by Damian Janowski, Senior Mechanical Engineer, DB ESG

Damian Janowski is DB ESG’s welding expert, having obtained an International Welding Engineer diploma. Damian is experienced in solving rolling stock welding problems and he also conducts welding audits, welding repairs and visual welding inspections. Damian has previously worked for both rolling stock and automotive manufacturers.

What is welding?

Welding is the process of permanently joining or fusing metallic (and some non-metallic) materials together by applying heat, pressure, or both, and then allowing them to cool. Whilst this method of joining materials is well-known, it is also considered a special process according to ISO 9000:2015 paragraph 3.4.1 Note 5. This is because the conformity of the resulting output cannot be readily or economically validated. In other words, to validate every weld, it would be necessary to cut and test them all, clearly this is not practical. As a result, inputs that make welding possible must be carefully controlled to ensure that the outputs (the welded joint) meet expectations.

What are these welding controls?

Welding is one of the most standardised special processes. There are a range of ISO and EN standards that govern various aspects of welding, from welding machines and calibration, to materials, consumables, and the qualification of procedures, welders, welding operators and inspectors. The generic series of standards defining quality requirements for fusion welding of metallic materials –EN ISO 3834 - describes how quality should be built into the welding management process and can be applied to any industry.

Which welding controls and standards apply to the rail sector?

In the rail industry welding controls are based on the generic controls mentioned previously, but there are additional specific requirements for the manufacture of rail vehicles. To standardise this area, another series of standards, EN 15085, was created, which incorporates EN ISO 3834 requirements and expands on them for the rail sector. This series of standards defines the quality requirements, as well as the design and production requirements for welding, that should be followed by manufacturers during new build or maintenance activities on railway vehicles and components.

What are the main criteria when specifying a weld?

During the welded component design there are various aspects to be considered, including: - Stress Factor – the weld strength (both static and dynamic) and Safety Factor – the impact of the weld on the safety of the component and the environment in case of a weld failure. These two main requirements must be considered during the design as per the requirements of EN 15085-3, but these are not the only aspects that must be reviewed. Other key aspects include: - access for welding and inspection, weld type, weld finish, acceptance criteria and impact on the surrounding area, these all play a vital role during the design.

Once all aspects have been reviewed and approved, the next step is to create a welding drawing that communicates the design intent to the manufacturer. There are standards that must be followed during the creation of the drawings e.g., welding symbols as per EN ISO 2553 should be used, specific welding notes shall be present on the drawing, all of which will enable the production of the welded component as per the design intent.

Why are the design criteria important and what can happen if they are not managed?

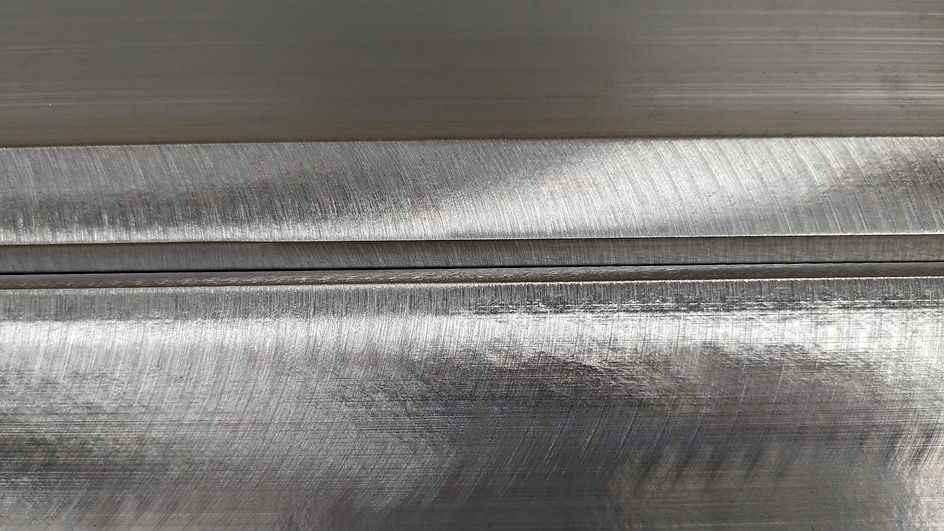

Not following the standardised route of component design can lead to welds that are too weak to withstand the design life of the component or are made from a wrong type of parent material, both of which could lead to catastrophic failure. These problems can include weld cracks, lack of weld penetration, porosity and underfill to name a few – all of which serve to weaken the joint.

Lack of consideration of the additional aspects can lead to a part design that may not be possible to manufacture or is overcomplicated and more expensive than it needs to be. If the component is not possible to manufacture or fails prematurely this can involve significant cost due to the need for re-design / re-manufacturing or replacement of non-conforming components.

Which welding controls apply to the maintenance and repair of rolling stock?

EN 15085-6 is a standard that covers maintenance welding requirements specifically for the railway industry. The scope of this standard is to define quality and design requirements, as well as the documentation needed, together with additional explanations on supplementary production weld tests.

Why are these welding controls important for the rail industry?

All the welding requirements are defined by industry experts to help ensure the structural strength of rail vehicles, this obviously guarantees safety for passengers, train operators, and the operational rail environment as a whole.

These welding controls ensure that welding outputs meet expectations, helping to maintain safety, and reducing the chance of costly repairs being necessary at a later stage. By adhering to industry standards, manufacturers can ensure that they are providing safe and reliable rail vehicles and components.

How can DB ESG help?

Hopefully, this blog has helped to explain the welding standards and controls that are in place, and why adhering to them is so important. I appreciate that this subject is complex but remember that DB ESG are here to help. DB ESG can address any rolling stock welding requirements, wherever they arise from, be it wear, corrosion, accidental damage, inspection and audit, or simply guidance and advice.

For further support email Damian.Janowski@dbesg.com